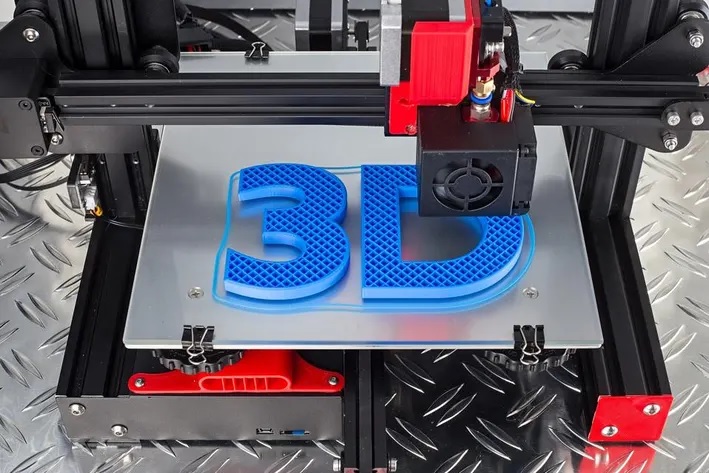

In the dynamic landscape of modern manufacturing, 3D printing has emerged as a revolutionary force, reshaping the way industries approach prototyping and production. This cutting-edge technology has transcended its initial applications and is now leaving an indelible mark across various sectors, from aerospace to fashion.

Aerospace Soars to New Heights

In the aerospace industry, where precision and efficiency are paramount, 3D printing has become a game-changer. Traditional prototyping processes often entail intricate and time-consuming methods. However, with 3D printing, intricate aerospace components can be swiftly and accurately reproduced, reducing both time and cost.

The ability to fabricate complex geometries with high accuracy has streamlined the prototyping phase for aerospace engineers. This not only expedites the development of new designs but also allows for rapid iterations, fostering innovation in an industry that demands cutting-edge solutions.

Healthcare: A Revolution in Customization

The healthcare sector is experiencing a paradigm shift with the integration of 3D printing. From crafting personalized prosthetics to manufacturing intricate models for surgical planning, this technology is fostering a new era of customization and precision.

3D printing enables the creation of patient-specific implants, ensuring a perfect fit and enhancing the overall success of surgeries. This level of customization not only accelerates the prototyping of medical devices but also opens avenues for tailored treatment strategies, marking a significant leap forward in patient care.

Fashion Forward with 3D Printing

In the world of fashion, where creativity knows no bounds, 3D printing has become a design powerhouse. Designers now leverage this technology to bring avant-garde concepts to life, pushing the boundaries of what is possible in the realm of clothing and accessories.

The rapid prototyping capabilities of 3D printing allow designers to experiment with intricate and unconventional designs, providing a tangible representation of their avant-garde visions. This not only accelerates the design process but also reduces material waste, aligning with the growing emphasis on sustainability in the fashion industry.

Automotive Advancements

The automotive industry, synonymous with innovation, has embraced 3D printing to enhance prototyping and production. Rapid prototyping of intricate parts allows engineers to test designs quickly and make necessary adjustments, expediting the development cycle.

Moreover, 3D printing facilitates the production of lightweight yet durable components, contributing to improved fuel efficiency and overall vehicle performance. The technology’s versatility enables the creation of complex structures that were once deemed impractical, showcasing its transformative impact on automotive design and functionality.

Conclusion: A Reshaped Landscape

In summary, the impact of 3D printing on production and prototyping across industries is nothing short of transformative. From aerospace to fashion, healthcare to automotive, the versatility of this technology has shattered traditional barriers, ushering in a new era of efficiency, customization, and innovation.

As industries continue to explore and harness the potential of 3D printing, we can only anticipate further breakthroughs and advancements that will reshape the manufacturing landscape for years to come. The journey of 3D printing’s influence is an ongoing narrative, one that promises to redefine the way we conceptualize, prototype, and produce in the ever-evolving world of modern industry.